How To Make A Paint Booth In My Garage

Like many of you, when I was a child, I loved reading car magazines. Any magazine that had an article about painting, definitely came home with me. My absolute favorite articles were about painting at home in your garage or driveway. But, what is the reality of painting at home? Tin the boilerplate enthusiast get practiced results painting a car in their garage? The answer is yes.

Thanks to advances in paint and equipment applied science, painting is easier than e'er. That is, if you follow some basic rules. More well-nigh the rules later. First, permit's talk almost setting up your dwelling house shop for paint and body.

Yes, it is possible to get smooth, clean clearcoat in your home shop. This 1967 Firebird was not painted in a professional paint berth.

Clean And Organize Your Shop

Information technology can't exist stressed plenty that yous need to outset off with a make clean store, merely why clean it, only to comprehend all that neatness with bodywork and paint dust? Starting with a clean shop makes it easier to go on information technology clean throughout the procedure. You should clean the shop every twenty-four hours, merely considering you lot're but cleaning up after that twenty-four hour period's work, the cleaning is easier and goes faster. Information technology is a lot of work, only will brand all the divergence in your paint job. Start by taking everything y'all can motility, out of the store (i.e. those crates of greasy parts, the clutter of old parts laying under the demote or stacked in the corners, etc).

Next, sweep and vacuum every inch of the store. Make certain to get all those spiderwebs in the corners of the ceiling. Any ataxia on the workbench(es) needs to be boxed up. Label the boxes, and so you'll afterward be able to detect that "special" bolt that you left by the vise. Wipe down all surfaces of the store: toolbox, bench, fridge, and walls. Invest in a few rolls of heavy-duty painter's plastic to wrap the boxes and any large parts. Try and stack everything neatly in out-of-the-mode places in the store.

Here, I'm spraying clearcoat on the Firebird in my homemade "paint booth."

Create a "Make clean" Atmosphere

Trunk-filler grit and over spray will accrue everywhere during the bodywork and pigment process. Cover all equipment, like welders or engine hoists, and things like store fridges with the plastic. For example, that place under the workbench where yous store things? Record a piece of plastic along the border of the workbench, creating a drapery that drapes to the floor. If demand be, cut a slot in the plastic to attain things. A few pieces of well-placed tape can deed every bit closures.

While yous're working, use a fan (or fans) to move the grit and over spray in the air, out of the shop. Never blow the sanding dust out of the shop with compressed air. It will go everywhere. Take the time to gently sweep or wipe it upward and dispose of it.

Clean Up Your Air System

Anyone who has used an air tool, like a Dual-Activity Sander (DA) or die grinder, for extended periods of time has experienced water coming out of the air hose. It's simple to assist keep your air system make clean and dry, every bit there are several low-toll remedies.

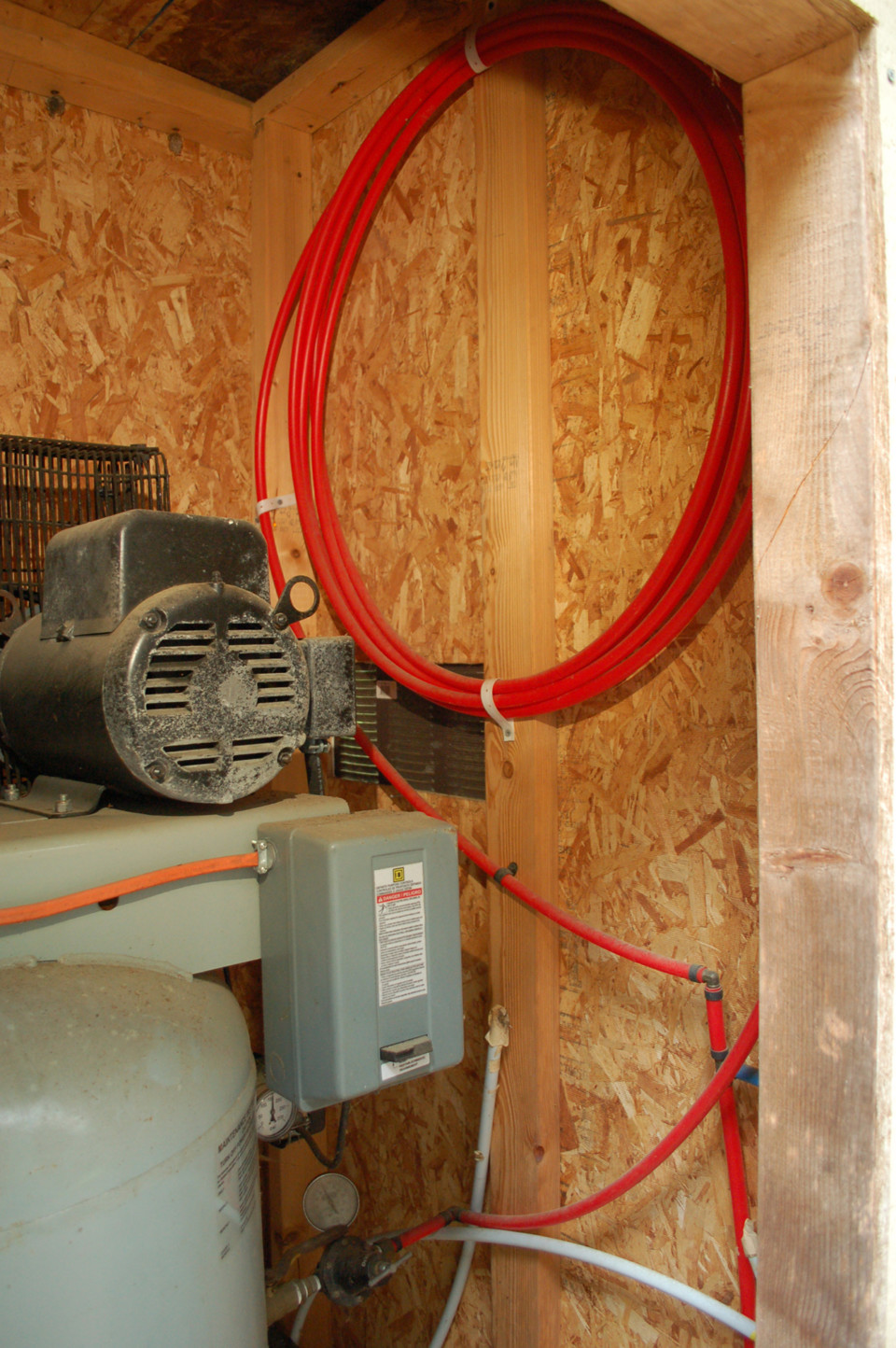

Here's a low-toll manner to assistance go along water out of your air tool or spray gun. Attach a 25-human foot air hose to the outlet on the compressor and loop information technology several times. Adhere the loops to the wall side by side to the compressor. Past running the hot air of the compressor through this, it gives the air a chance to cool off, and near of the condensation stays in the loops. That means less water gets into the shop's air lines.

Ever run across someone mount a water separator right after their compressor? That's not a expert idea. The air coming out of the compressor is hot, and as the air cools in the air lines (after the separator), condensation forms. One way to brand a low-tech air drier is to connect a 25-human foot air hose to the compressor, scroll it up, and attach it to the wall. Then, hook some other hose to it. This rolled hose will give the air a chance to absurd, and the condensation remains in the coils.

Some shops take hard lines with water separators at the air outlets, and some will have a unmarried air hose that goes straight from the compressor to the spray gun or air tool. If your shop is like the latter, then have the time to hook up a water separator to that air hose. Attach a separator to the wall, then run a second air hose from the separator to the tool or spray gun. This volition assistance keep the water from getting into your pigment. If yous still take water coming out of the end of the air hose, a simple, cheap inline water filter should practice the play a joke on. They mountain straight to the stop of your air tool or spray gun. You tin can buy them at a habitation comeback store for less than $15. Always make sure to bleed the h2o of out of your air compressor on a weekly basis.

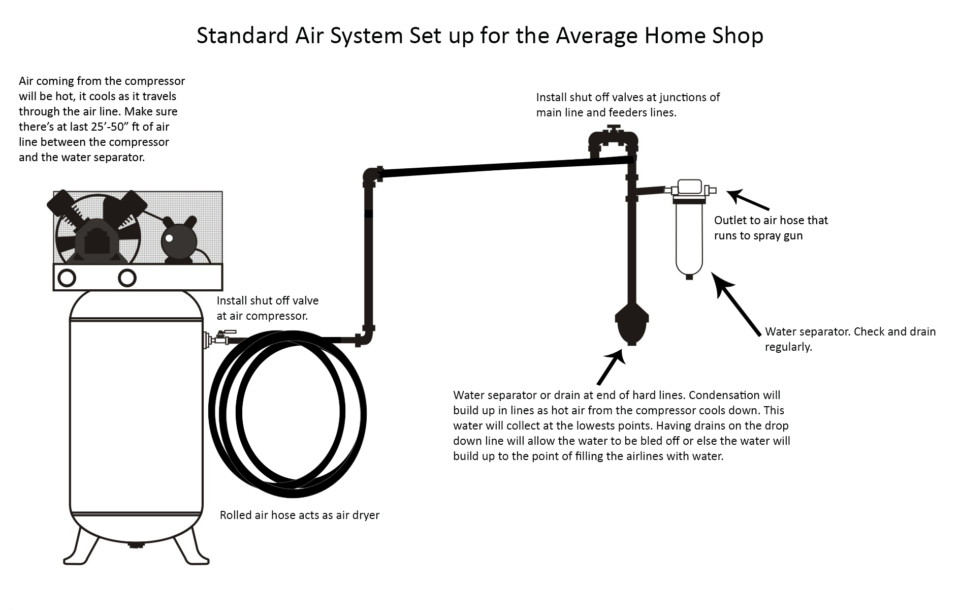

This diagram shows the standard air line gear up for the average shop. By keeping the level of the store's air lines a little higher than the air outlet for the compressor, it helps proceed the h2o at the compressor end of the lines.

Lighting Your Pigment Area

If yous've been waiting to add together more lights to your shop, this is the perfect time. For the perfect paint job, your going to need non just lights on the ceiling, just besides, on the walls of the shop. It'due south low cost and easy to create your own "berth" lights. Using an LED light fixture (about $twenty each at the home comeback store), you lot tin stand it on end and add 2x4s to create a base. You will have portable lighting that will illuminate the sides of the machine. You can move these lights to wherever you lot demand them in the shop. For around $125 you tin fabricate four of these lights.

This is an old "paint berth" lite I fabricated 20 years ago. All that's needed is 4 to 6 LED shop-calorie-free fixtures and some 2x4s. Measure and cutting a 2×4 to fit on the back of the light fixture, fabricate a base and adhere it to the stop of the low-cal. These tin exist moved where ever they're needed. Single-LED work lights tin as well come in handy lighting up dark areas in the shop.

Create A Mantle Wall

You lot'll desire to save this step until y'all've completed the bodywork and priming, and are ready for color. To create a temporary pall wall or makeshift spray booth, yous'll need a 100-human foot roll of 4- to half-dozen-mil plastic. Using a staple gun, cover the ceiling of the shop. If you have hanging lights, take them down and make clean them. Run the plastic over the ceiling, then reinstall the lights. If y'all have lights directly mounted to the ceiling, run the plastic over the light fixtures. Only practise this with fluorescent or LED lights.

Next, decide how much working room y'all'll need around the motorcar to paint. Run a plastic curtain along that measurement, stapling the top of the curtain to the ceiling. Cut off any excess that lays on the flooring. Make sure to leave a gap along the floor in the front and in the dorsum of your "room" to allow for air menstruation.

Here's a view of the plastic curtain walls I hung in my store. The floor is also covered with plastic, every bit the over spray can state on the flooring. If you take a overnice epoxy coating on the floor, you might desire to consider protecting it like I did here. An advantage of creating a plastic sheeting mantle-wall paint area, is you can make it as big as your garage if yous want. Hither we had plenty of room to accommodate all the parts of the car.

The Rules

The above steps are sure to help you put together a temporary paint booth and then you tin can pigment at home. If y'all follow the to a higher place steps, yous should be able to get the quality results you are looking to achieve. Retrieve the "rules" I mentioned at the beginning? Below are some simple rules that can certainly assist you achieve great results.

- Keep it clean. Any dust or dirt that is on a surface of the shop might get into the paint.

- Silicone and oil are the enemies of pigment. Never spray things similar WD40 or tire polish in or around your shop while in that location's any kind of bodywork or paint going on. One fourth dimension a friend was spraying tire shine exterior my store. It drifted in through the door and landed on the surface of the car and ruined the paint! Think of your shop as a "silicone-free" zone from the start of bodywork until the last coat of clear is sprayed.

- Don't inexpensive-out when information technology comes to bodywork and pigment products. You don't take to use the nigh expensive products, merely exercise the inquiry and discover good-quality products to use. Your paintjob is only as good as the products used.

- Make sure to invest in several disposable paint suits with hoods. Wear ane when priming to protect yous from the paint. Salve the other for the base of operations and clearcoat. About of the grit that volition become into a paintjob will come from the painter.

- Clothing the proper respirator and go on it in a zipped plastic handbag when not using information technology.

- To save your hands, option upward a box of Nitrile gloves. Apply them whenever you are using chemicals like thinner, and mixing or spraying paint. I even vesture them when doing bodywork to save my easily and to keep oil from my hands from getting on the paint surface.

- Be aware of any HOA or zoning rules in your expanse about painting at abode. The last thing you lot want to meet is a town official pulling up because your neighbour complained about paint fumes coming from your garage.

Chances are those plastic pall-walls will be up for a while. You're going to become tired of them. I sure did. The pigment procedure for the Firebird lasted two weeks, equally I had to paint Real Burn flames on the car. A quick solution was to take down the pall wall on the side of the garage that had the toolboxes and work bench, leaving the plastic hanging on the ceiling and the other three sides. Once the artwork was complete, information technology was like shooting fish in a barrel to hang up a new curtain wall on that one side and clearcoat over the artwork, finishing the paint process.

Now that your store is fix for bodywork and paint, always recall the best tool in the shop is common sense. Think your style through the process. The bodywork and paint stage of a car build is not the time to exist impatient or spontaneous. Good Luck with all your painting projects!

Source: https://www.chevyhardcore.com/tech-stories/paint-body/paint-booth-home/

Posted by: huertanesintlefor.blogspot.com

0 Response to "How To Make A Paint Booth In My Garage"

Post a Comment